Lary rubber sole injection machine has been improved and made a break through in market !

- Share

- Issue Time

- Feb 20,2017

Summary

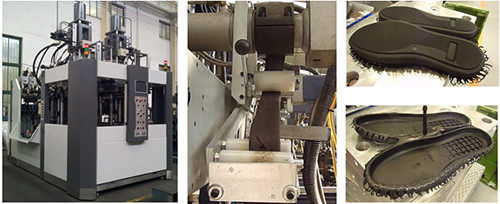

Our typical product—Lary LRS165 rubber sole injection machinehas been improved recently and meet high quality requirement !

Our typical product—Lary LRS165 rubber sole injection machinehas been improved recently and meet high quality requirement !

Rubber injection molding machine, is shortfor rubber injection machine;a technology of rubber molding products ,mainly used for the production of rubber moldedproducts, such as electrical insulation parts, shock pads, seals, soles andindustrial rain boots and so on. At present, It has been widely used at homeand abroad.

The main features of the rubber injection machine:

1. Simplify the process, to achieve hightemperature vulcanization of rubber products, shorten the production cycle;

2. Product size is accurate, physical andmechanical properties of uniform, high quality, thick-walled products,especially the formation of vulcanization;

4. Easy to operate, reduced laborintensity, high degree of mechanization and automation;

Injection molding machine and its moldbody is more complex, large investment, maintenance level requirements arehigher, and more for large quantities of molded products production;

Our Products

- High Quality. It brings more uniform density and thickness by high technology injection process.

- High Efficiency. We try to shorten the curing time of each cycle, one worker can operate 4-6 moulds at the same time, implyment the fully automatic control system including feeding,weighing,exhausting ,mold into/out and open.

- Low Waste . It can reduce more flash waste and increase the rate of finished products, keeping the heat energy&electric energy to a minimum.

- CE Certification, The product has been verified on a voluntary basis and meet the requirement of the Safety Compliance Mark of ECM ,giving you more at ease use

- Soft Injection. Softer injection can extend the die life,suitable for most kinds of rubber material injection,and mix other materials.

- Eliminate Color Mixing. When using pre form inserts with different colors,single color injection machine will eliminate more than 95% of the color mixing.

- ……………………………………………………

- ……………………………………………

- ………………………………

- To provide more clear edge between different colors

- To satisfyt more complex production of the mold,

- To be suitable for more kinds of rubber

- To express more detailed patterns

- To give you more precision

- We are doing our best......

The specification of the injection machine;

the maximum injection volume of themachine to represent the unit is cubic centimeters; general equipment factoryshows the maximum injection volume, is the theory of the largest injectionvolume, the actual machine manufacturing and use of the process of deviation,making the machine the largest maximum injection And the maximum theoreticalinjection volume has a certain deviation;

The theoretical injection volume refers tothe maximum amount of plasticized melt (cm3) that can be introduced by theinjection device in the maximum stroke of the screw (plunger) in the injectionmolding machine. The theoretical injection volume is the main performanceparameter of the injection molding machine. From this parameter you can knowthe processing capacity of the injection molding machine, which can determinethe maximum quality of an injection molding plastic products.

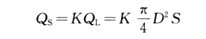

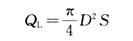

National standard GB /T 12783-1991 provides that the theoretical amount of injection volume with thematerial melting state of the quality (g) or volume (cm3) said. At present, thedomestic and international countries with the volume (cm3) marked more, becausethe material volume and material density of the molten material has nothing todo, this labeling method to adapt to any plastic measurement.The theoretical injection volume iscalculated as follows

Where QL - thetheoretical injection volume, cm3;D - screw (plunger)diameter, cm;

S - the maximum stroke of the screw(plunger), cm.

As the screw (plunger) outside the diameterand the barrel between the inner diameter of a movement of the assembly gap,when the screw (plunger) to promote the melt forward, by the nozzle nozzlediameter and material and the barrel wall friction and other effects , Therewill be a part of the material from the gap back. In addition, the melt coolingwill have a certain amount of shrinkage needs to be added. Therefore, theactual injection of injection molding machine is less than the theoreticalinjection volume, the calculation needs to use the coefficient K valuecorrection, K value and screw (plunger) structure and parameters, diameter andgap, the size of injection, Flow rate, back pressure size, mold structure,product shape and the nature of the plastic and other factors. When the screwhead has a check valve, take the K value of 0.9; if only consider the meltback, take the K value of 0.97.

Ie the actual injection volume

If you know the quality of plasticproducts, in the choice of injection molding machine, the molten state of thevolume of plastic converted to density. which is

Where Qs - injection molding machine actualinjection volume, g;

ρr - density of plastic in molten state, g / cm3.

- High Quality. It brings more uniform density and thickness by high technology injection process.