Lary CE approved rubber sole injection moulding machine

- Model

- LRS165

Item specifics

- Condition

- New

- Place of Origin

- Zhejiang, China (Mainland)

- Brand Name

- LARY

- Model Numbe

- LRS165

- Voltage

- 220V/380V

- Total Power (W)

- 55Kw

- Dimension (L*W*H)

- 3680X2020X(2750~3250)

- Weight

- 9.5Ton

- Clamping force(KN)

- 1650

- Clamping Stroke(mm)

- 300

- Space between heating plate(mm)

- 230~480

- Heating Plate Size(LXW mm)

- 460X340

- Power of heating plate(KW)

- 12X2

- Mould size(LXW mm)

- (400~460)X(300~360)

- Mould thickness(mm)

- 80~440

Review

Description

LRS165 Lary CE approved Lary rubber sole injection moulding machine (Two Stations)

Product Details

Quick Details

Packaging Delivery

Packaging Details: warpping film, the overall unit put intp a 40HQ Container

Delivery Details: Shipped in 90 days after payment

LRS165 Lary CE approved Lary rubber sole injection moulding machine (Two Stations)

Product Description

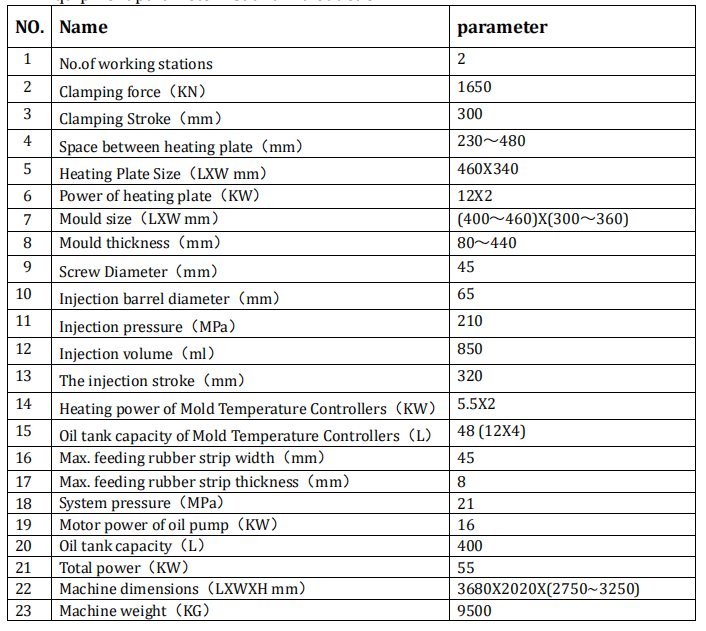

Specifications of LRS165 Lary CE approved rubber sole injection moulding machine (Two Stations)

Meet the high request of rubber shoe soles

1. Automatic feeding rubber, plasticizing preheating.

2. Automatic weighting, injecting rubber into the mold cavity.

3. Automatic vacuum or exhaust.

4. Automatic mold into/out and open the mold.

Each Worker can operate 4-6 Stations (2-3 Machines)

Each Station can produce 20-40 pairs of shoe soles per hour

Pictures of LRS165 Lary CE approved rubber sole injection moulding machine (Two Stations)

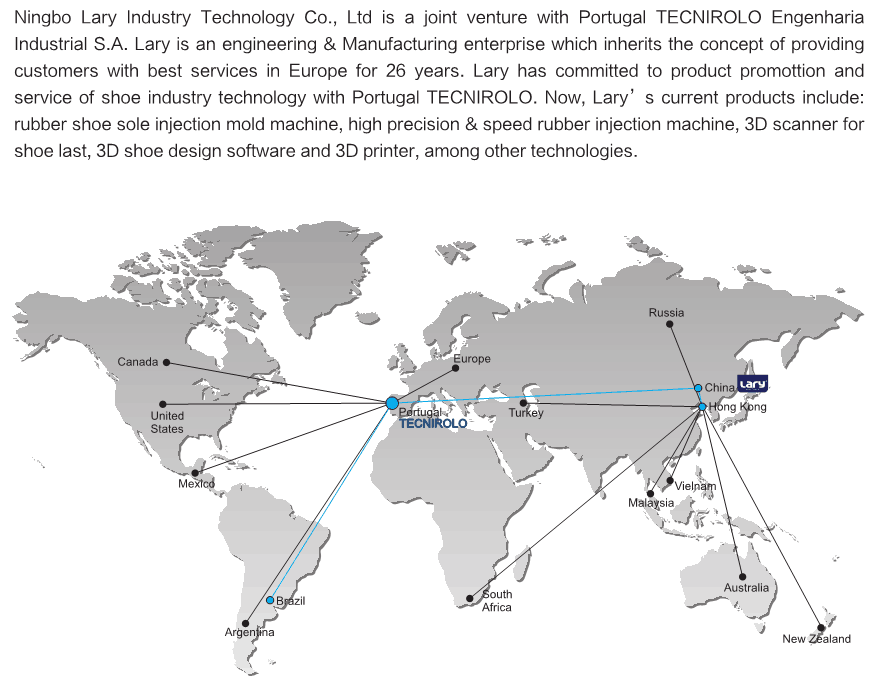

Company Information

Certification

Our customers

Our team

FAQ

Why choose US?

1. European most advanced technology, specialized in the Rubber ShoeSole Injection Molding technology. Compact construction, Fully automatedproduction.

2. Only need to put the rubber strip into the feeder, you canachieve automatic metering, preheating, injection, and automatically moving outthe mold, opening mold. Full automated production process greatly improved productionefficiency, reducing labor intensity, protecting the mold.

3. Each Worker can easily operate 6-8 stations(3-4 machines), and each station can produce 22-35 Pairs of Shoe Soles per hour.

4. The process of injection after clamping, greatly reducing theproduct flash and trimming costs. The product is more compact, to improve theintrinsic quality of the product.

5. With humanized interface, you can set the Curing Time, InjectionVolume, Preheating Temperature, Curing temperature, Exhausting Parameters. And theFault Diagnosis system can guide the maintenance staff to solve the problem inthe shortest time.

6. Equipped with automatic Mold Change system. A mold can bereplaced within five minutes.

7. Advanced energy-saving hydraulic control system can support 24hours’ continuous operation, with quickly response energy efficiency.

8. For Insert Color Process, single color injection machine willsolve the rubber mixing problem easily, greatly improving the yield of theembedded color products, quality, and reduce costs of artificial re-treatment.

9. Optional Vacuum System, completely solve the problem ofproducts with air.

10. Two kinds of heating systems are available, electrical heatingand oil heating.

You will have 16 hours support everyday!

Future will have our branch in Turkey.

More professional, our Portugal engineers have 10 years' experience for rubber injection,

and they learn quickly, always pay attention to the latest technology on the world.

How about your payments item?

Payment Item: 40% deposit after confirming the drawings and 60kijuu% balance afterconfirming the scanner (before delivery).

Delivering time?

Generally, 90 days after we confirmed both side.

Welcome to visit us!

It is time to change!

Our injection moulding machine is highly automated production, remove the tedious manually

operation of traditional vulcanizing machine, the pursuit of high quality, high efficiency, to meet

the demand of rapid production. It is time to use new technologies, using Lary high quality high

efficiency rubber shoe making machine.

Amy Ren

Ningbo Lary Industry Technology Co., Ltd

Add: No.9 East of Jingu middle Road, Yinzhou District, Ningbo City, China

Web: www.lerytec.com www.nbmech.com

Tel: 0086-754-88033926

Fax: 0086-754-88137126

Mob: 0086-13958255267

Email: amy@larytec.com