SLD series continuous powder metallurgy steel belt type high temperature reduction furnace

- Model

- SLD series

Item specifics

- Product name

- reduction furnace

- Other name

- Powder Metallurgy

- Preheating temp.

- 750℃

- Reduction temp.

- 980℃

- Belt width

- 1000-2000 mm or Customized

- Heating power

- 375-1800KW or Customized

- Material of Muffle

- Stainless steel or ceramic or Customized

- Control chamber

- Customized

- Material of belt

- SUS316 or Customized

- Heating element

- SIC or Customized

Review

Description

Keywords:reduction furnace, high temperaturemuffle furnace, steel belt reduction furnace, temperature sensor furnace, ultrahigh temperature furnace, powder metallurgy reduction furnace

Product attributes:Product name: reduction furnace

Application: Powder Metallurgy

Preheating temp.: 750℃

Reduction temp.: 980℃

Belt width: 1000-2000 mm orCustomized

Heating power: 375-1800KW orCustomized

Material of Muffle: Stainless steelor ceramic or Customized

Control chamber:Customized

Material of belt: SUS316 orCustomized

Heating element:SIC or Customized

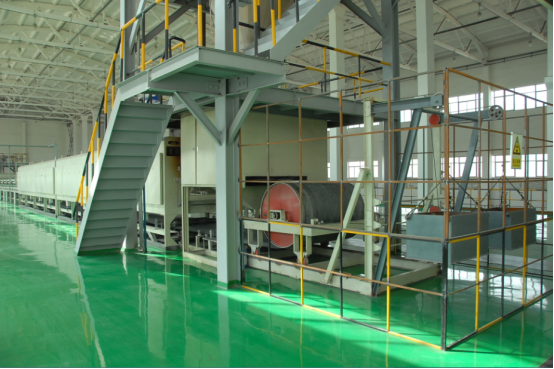

Pictures:

Features:

1) The equipment features largeoutput, simple structure, easy to adjust and convenient to control quality. Itis the upgrading and updating product for bi-tube, quadri-tube and multi-tubereduction furnace widely used at home and abroad. The complete equipment iscomposed of feed section, reduction section, slow cooling section, coolingsection and discharge section.

2) The feed section includescharging deck and inlet muffle. On the charging deck, there is a distributingdevice which can move from right and left along with steel belt to ensure theuniformity of materials on the belt.

3) The muffle of reduction sectionadopts heat-resisting steel plate. The shell of muffle is in corrugate shape toincrease the strength of muffle so that it can slide on the SiC plate afterexpanding by heat.

4) The feed inlet and the dischargeoutlet adopt roller sealing with gas curtain and fiber curtain sealing, whichfeatures sound sealing performance and low gas consumption.

5) The material conveying system iscomposed of thermocouple, PID regulator with digital display and solid-staterelay, which forms closed loop control system to realize automatic accuratetemperature control.

6) The gas flow meter displays theflow rate of protective atmosphere. The rates of all kinds of atmosphere can beadjusted according to process requirement.

7) The temperature of cooling wateris automatically controlled by the make and break of magnetic valve controlledby temperature controlling elements.

Specification:

| SLD-3 | SLD-5 | SLD-7 | SLD-10 | SLD-20 |

| (mm) | 1000 | 1000 | 1000 | 1500 | 2000 |

Preheating temp (℃) | 750 | 750 | 750 | 750 | 750 |

Reduction temp (℃) | 980 | 980 | 980 | 980 | 980 |

Heating power (KW) | 375 | 600 | 750 | 936 | 1800 |

Annual output(iron powder) (T) | 3000 | 5000 | 7000 | 10000 | 20000 |

Speed of belt (mm/min) | 50-250 | 50-250 | 50-250 | 50-250 | 50-250 |

Atmosphere Reduction | Cracked Ammonia | Cracked Ammonia | Cracked Ammonia | Cracked Ammonia | Cracked Ammonia |

Material of belt | SUS316 | SUS316 | SUS316 | SUS316 | |

Heating Element | Sic | Sic | Sic | Sic | Sic |

Application:

SLD seriessteel belt type refining reduction furnace (also known as steel belt type ironpowder refining reduction furnace or steel belt type copper powder refining reductionfurnace) is mainly use in the powder metallurgy industry to reduce metalpowder, such as iron powder, copper powder, cobalt powder, molybdenum powder,tungsten powder, and so on. It can also be used in the calcining and refiningreduction of metal salts, such as cobalt oxalate, APT (magnesiumpara-tungstate), and so on, also used in calcining and refining reduction ofmagnesium hydroxide and lithium iron phosphate.

Factory:

Company:

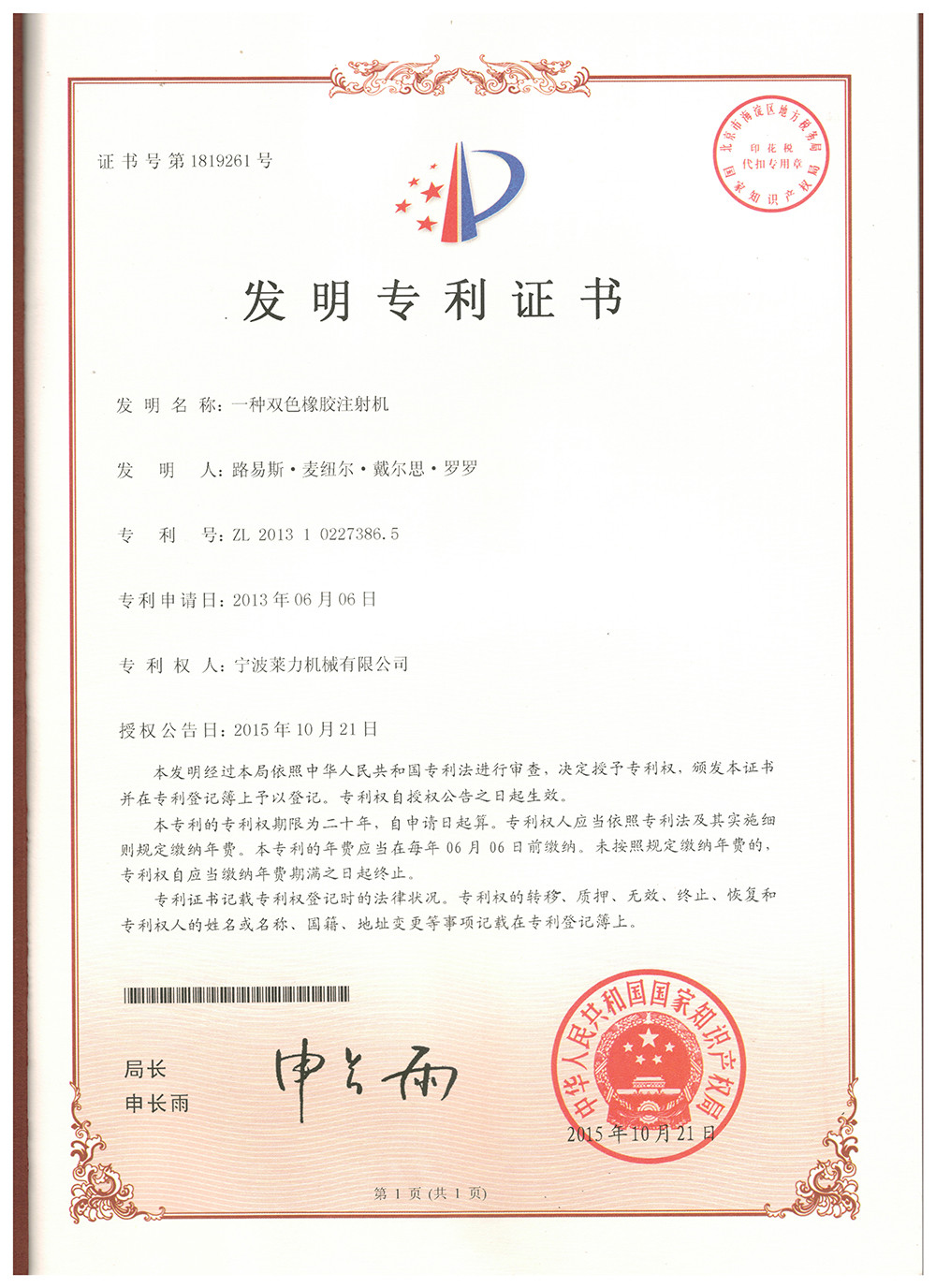

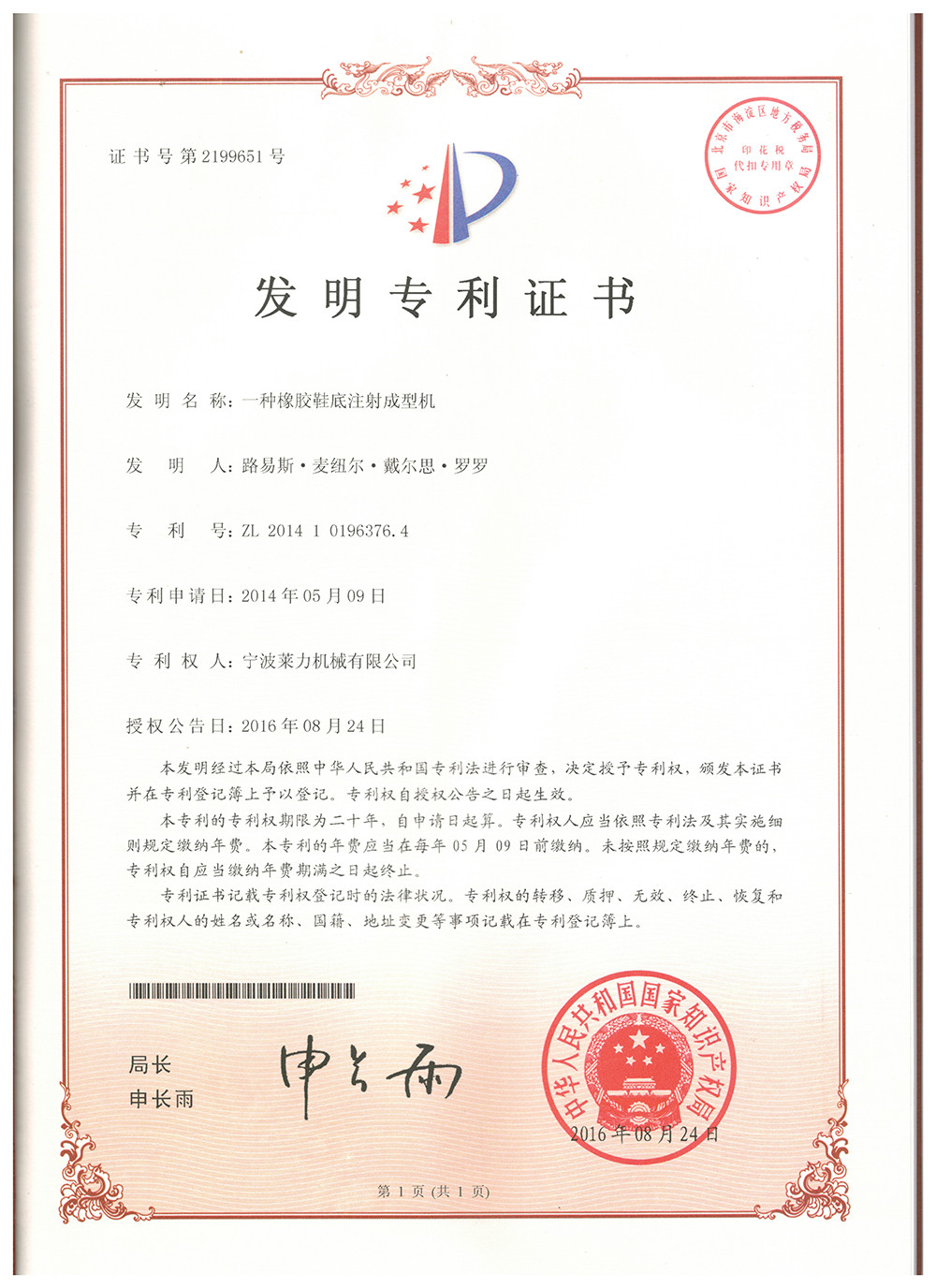

Ningbo Lary Industry Technology Co., Ltd is ajoint venture with Portugal TECNIROLO Engenharia Industrial S.A. Lary is anengineering & manufacturing enterprise which inherits the concept ofproviding customers with best services in Europe for more than twenty years. TecniRolo - Portugal andLary Industry - China are a group of companies that work as a global solutionprovider for an international network over of 16 countries.

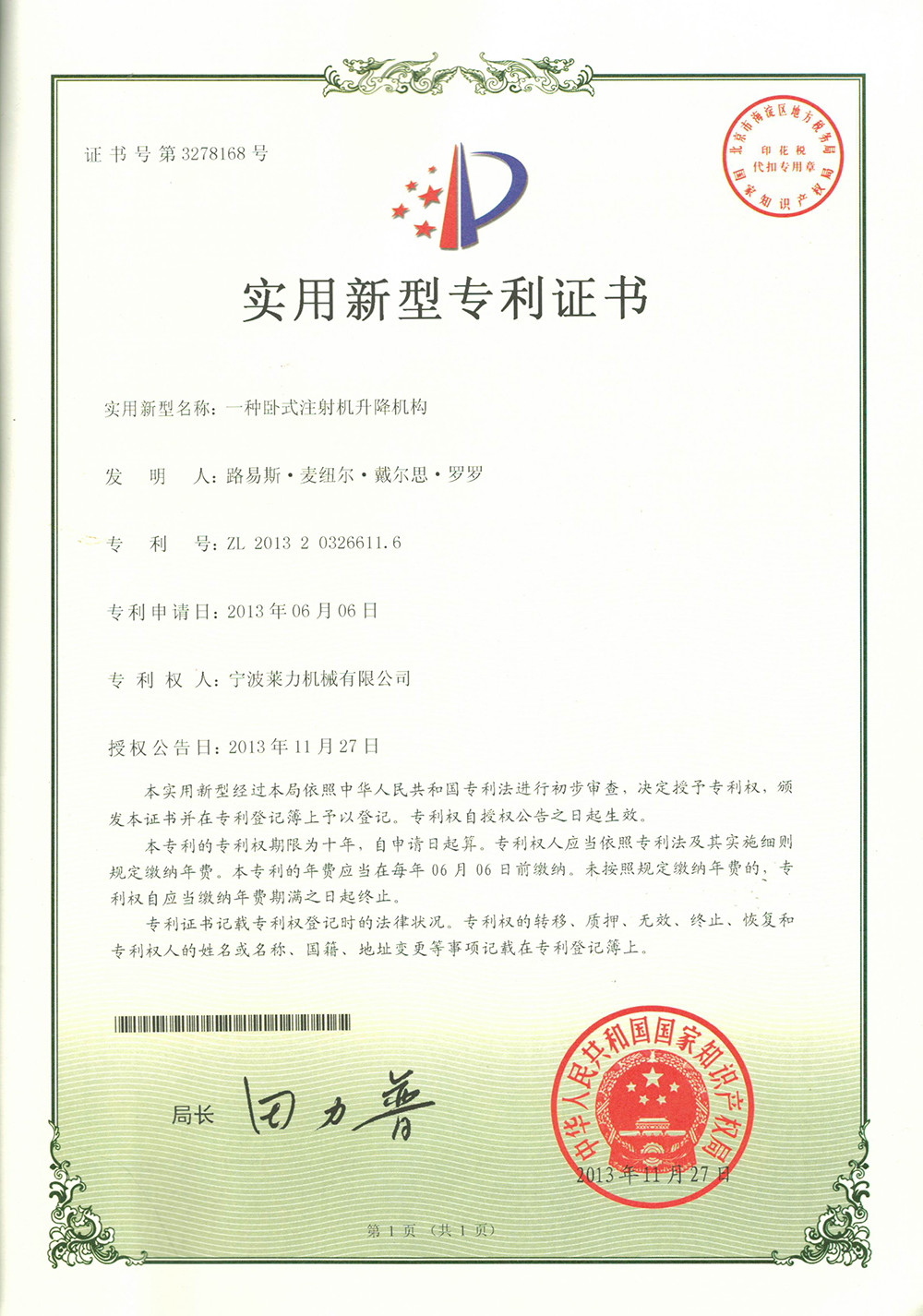

Certification:

Customers:

Paymentsand Delivering:

Payments: 40% depositby T/T after confirming thedrawings and 60% balance by T/T before delivery.

Delivering: 90 -120 daysafter we confirmed both side.

Contactus:

Amy Ren

Ningbo Lary IndustryTechnology Co., Ltd.

Ningbo

Add: No.9 East ofJingu middle Road, Yinzhou District, Ningbo City, China

Web: www.larytec.com

Tel:0086-754-88033926

Fax:0086-754-88137126

Mob: 0086-13958255267

Email:amy@larytec.com

Welcome to visit us!